Saws is a VCO giving a fat triple oscillator sound with a single V/O input and output.

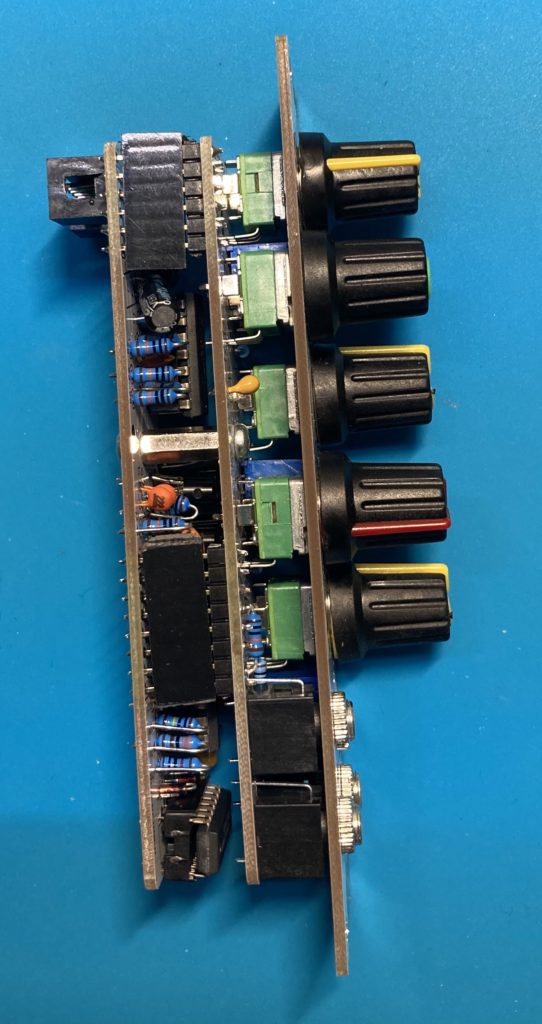

The front panel has switches to activate or deactivate each of the three saws, so you can tune them clearly, or run it as a single or double oscillator.

Calibration trimmers are visible on the front-panel so tuning is easy.

Saws is a single VCO with a triple sawtooth internally and is capable of a chorus-pad, or a detuned raw bassline, or an individual sawtooth VCO with V/O and FM!

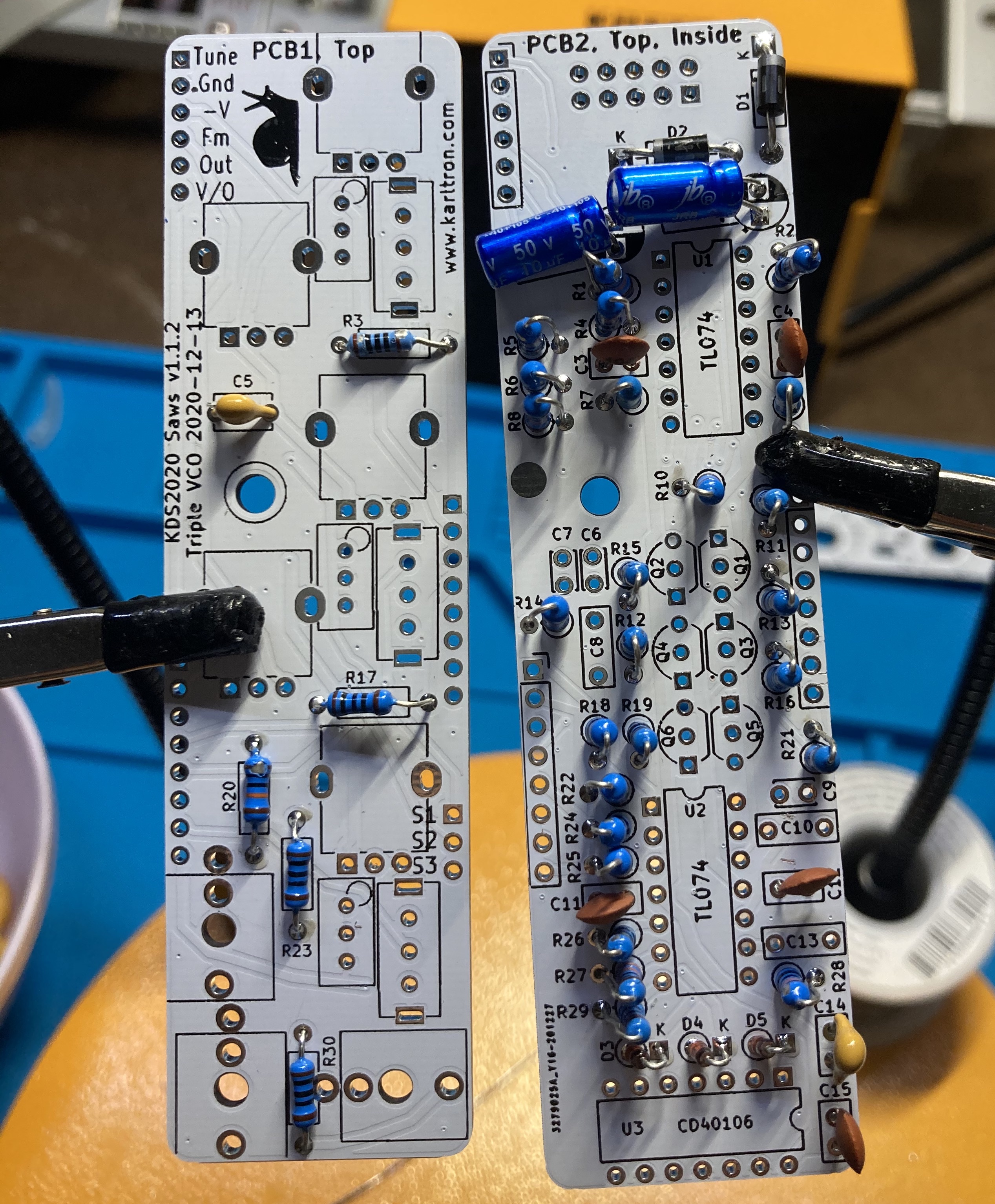

Build Guide and BOM for v1 (THT) and an ibom html.

Build Guide and BOM for v2.0 (SMT) and an ibom html.

| Kit Type | Price | Note | |

| PCB/ Panel Set | $25 | a few smudged panels available for $8 discount | |

| Full Kit (incl PCB) | $100 | prepared for THT edition only | |

| Built and Tested | $150 |

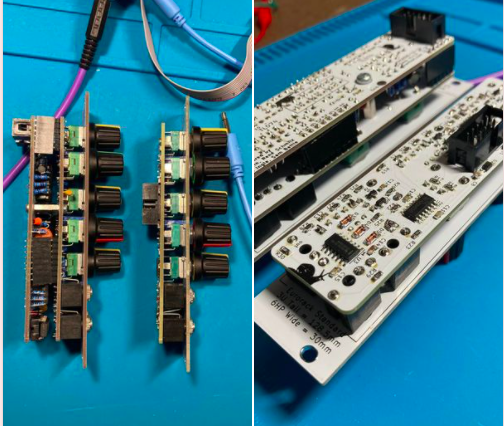

Currently available in your choice of throughhole or surfacemount technology. They play the same.

This circuit, like every circuit, is a modification of stuff I learned online and also from here.

Calibration Procedure:

This is an analog VCO using the -18mV/octave standard, given by a voltage divider at the input. Like all analog gear it needs calibration after construction due to component differences, or when the seasons change environmental parameters.

The easiest way to calibrate is with a nice V/O keyboard (or other switchable +/- 1 volt input) and a frequency counter (perhaps in an oscilloscope, or guitar tuner). Do each of the three separately by activating the front panel switches.

First, turn it on and let it warm up for a few minutes.

Then, with 0V input at the V/O jack, set the coarse tune so you have a tone you want in the middle of your tuning range, maybe 100 to 600 Hz. Add exactly 1V, and note the new frequency. With a hand calculator (maybe on your phone) divide the new frequency by the 0V frequency. If it’s >2.05 then you’re too sharp, crank the trimmer counter-clockwise. If it’s <1.95 you’re too flat, and need to trim clockwise. Repeat until 1 volt gives exactly a doubled frequency. That’s V/O tracking!

I also recommend the visual tuner app for speeding up the process.

NOTE: THT construction means the parts are through-hole and have big metal leads. It’s compact with standing resistors, and doable by hand if you have minimal soldering experience already. You don’t need any special tools beyond a soldering iron and snips. These tools are not included with the kit.

I did integrate an expansion port internally making available the three saws so an expander could someday remix them or clip into squares. That didn’t happen yet because it needs six more knobs and I wanted this to be a simple 3xVCO.

Version 2 is a single board done in surface-mount-technology. At the moment both are available at your choice in PCBs or built (no kits for SMT edition right now).

Troubleshooting Tuning. It’s normal for the three analog oscillators to have slightly different tunings, you will find the phasing sound when two oscillators are quite nearly the same frequency to happen when the fine tune knobs are not in exactly the same position. I like to set one of them vertical, tune the second to phasing, then remove and adjust the knob so that it points upward as well. Then do the third. This shifts the range for each fine tune pot and puts your equal tone at the upright position.

These differences could be from imperfections in many parts of the circuit, but are primarily caused by the transistor pairs having differential gain. You can try matching the transistors. Only once has the tuning been so different that knob adjustment wouldn’t cut it (osc3’s min freq was about the same as osc1’s max). This happened on an SMT edition; I had to change out the PNP for a new one that was closer to the others. Swapping the NPN and the capacitor had no effect, all of the tuning scale error was from the PNP’s coefficient, which had been poorly matched to the other two. Usually you don’t have to worry about matching the transistors, but check them if your three are too far apart.